Systems are getting smarter. This poses new challenges for the test environment. Realistic simulations of vehicles and their surroundings require dynamic interaction between the test bench and the test object. Count on our cross-domain expertise to meet your demands for high availability, reproducibility, traceability, and more. We draw on this diverse skill-set to optimize test environments in accordance with ISO 26262, integrate solutions into legacy architectures, and ensure flexibility and modularity.

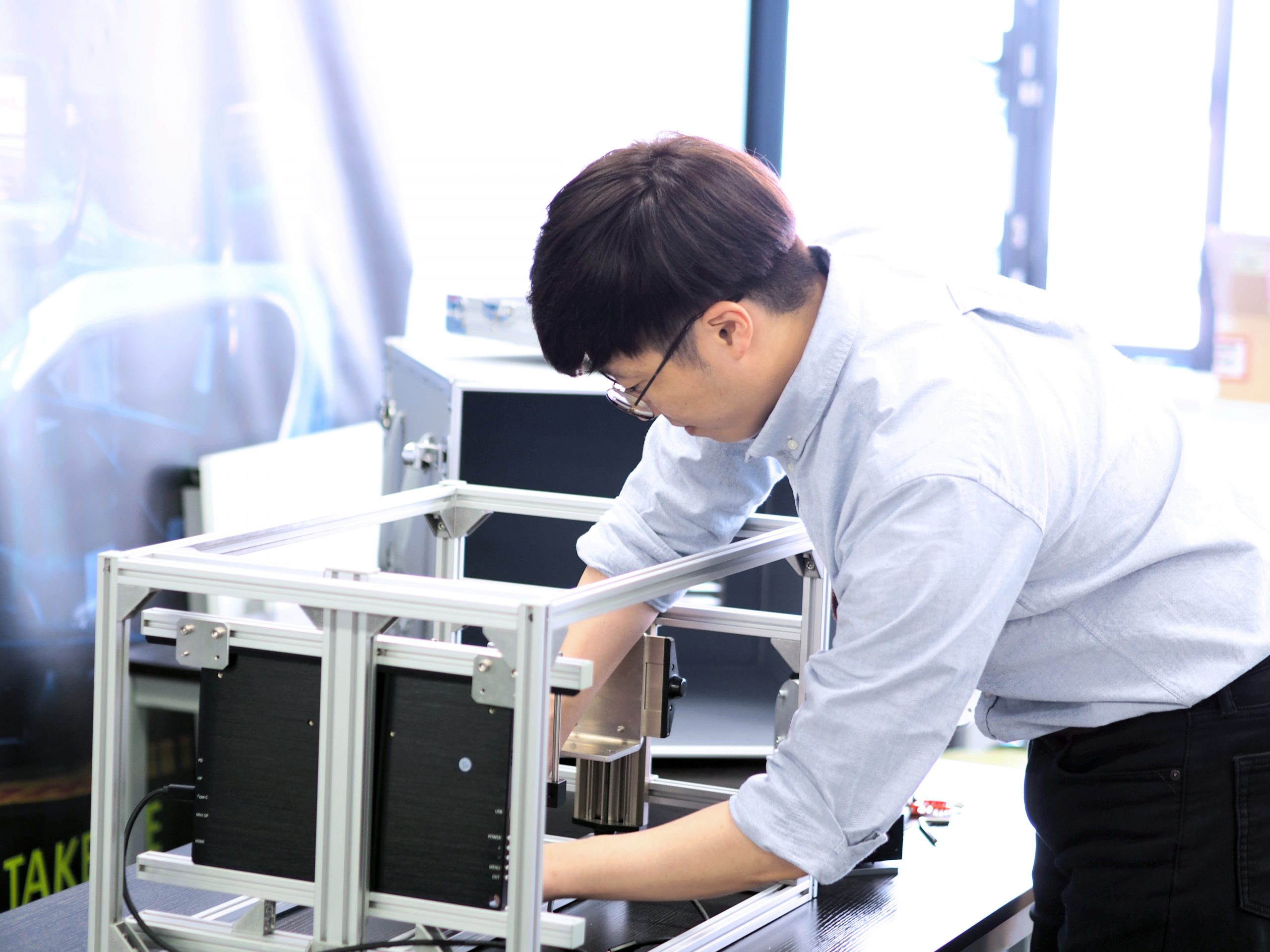

We take a holistic approach to development that factors individual industries and customers’ challenges into the equation. These services cover everything from definition and conceptualization to end-to-end systems (software and hardware) engineering and field support.

In the conceptual phase, we tackle requirements engineering tasks such as tool qualification and standards conformity – and all other demands associated with determining specifications, building machines, designing tests, and consulting on technologies. As a vendor- and systems-agnostic service provider, we always puts the customer’s needs first. We rely on modular software architectures and state-of-the-art data management for overall systems engineering. Once the project wraps up, we will be happy to provide follow-on services and support to cover maintenance, lifecycle management, and the like.

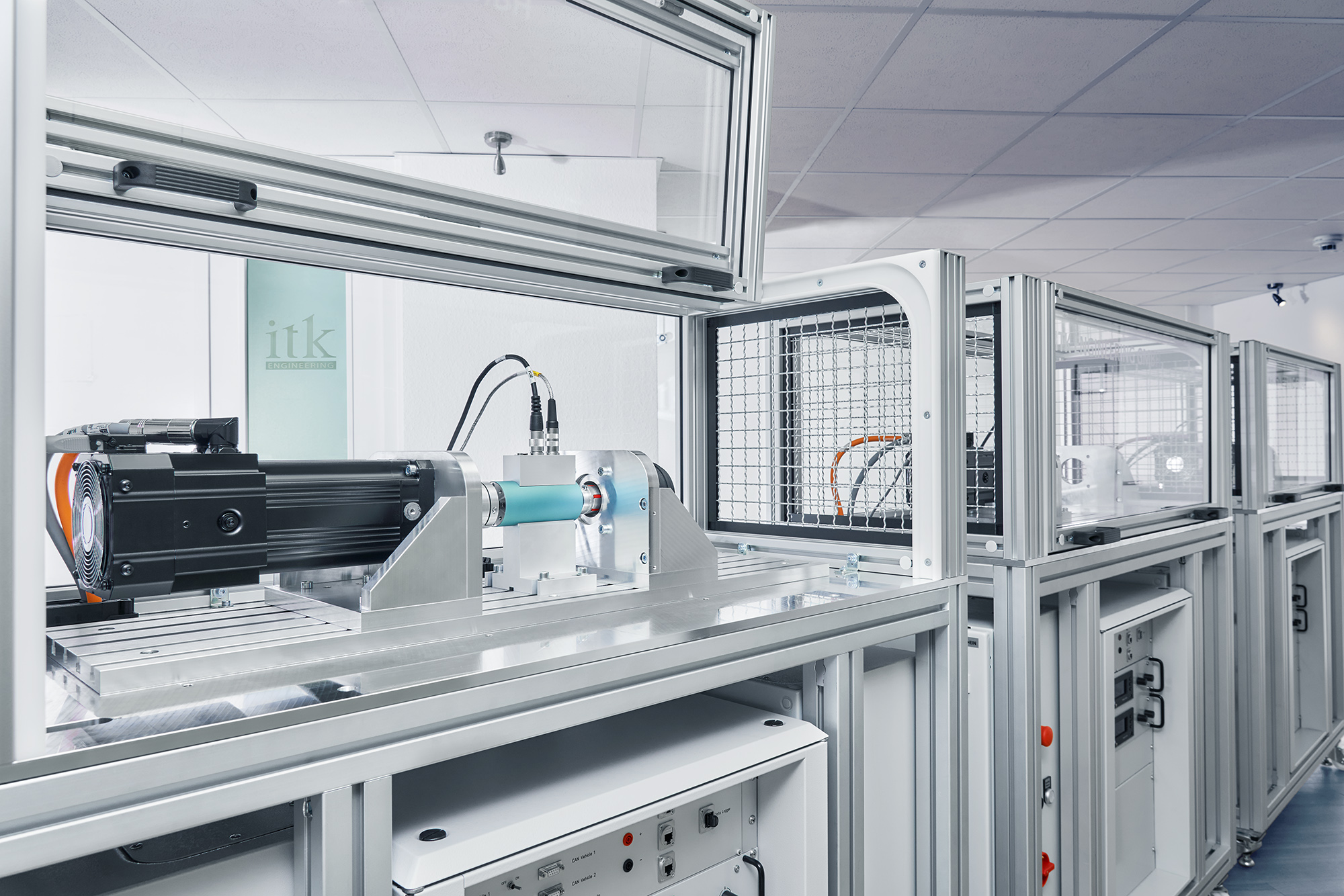

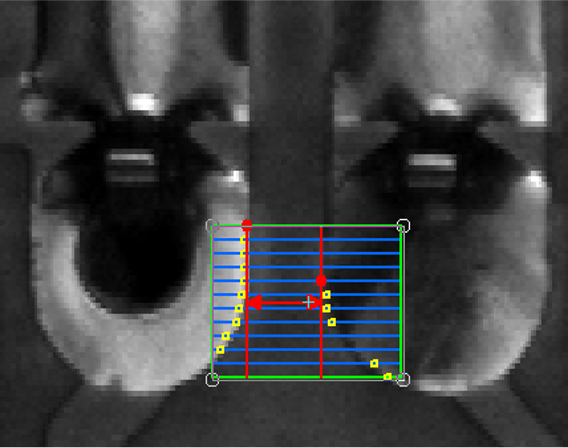

You can actually verify and validate mechanical components, actuators, sensors, control units, and the way they interact in one and the same test environment. With this integrated testing method, a hydraulic or other actuator generates the desired load profiles for the mechanical component while a residual bus simulation tests the electronic function. The test bench controller is crucial to capturing very accurate results.

– Powerful algorithms and an automated controller ensure high-quality control and very accurate test results

– Scales integrated into the mechanical design for a fully reproducible test setup (adjustable for the tested object and actuator)

– Haptic testing even without vehicles, with fewer road trips to cut costs

– Wide range of use cases from conventional steering systems to (semi) autonomous EPS applications and steer-by-wire systems

We serve as your general contractor for specific challenges. Anything goes, from optimizing legacy systems to delivering turnkey component test benches.

– End-of-line quality assurance using computer vision

– Steering & active vehicle components

– Power packs

– Actuators with position sensors